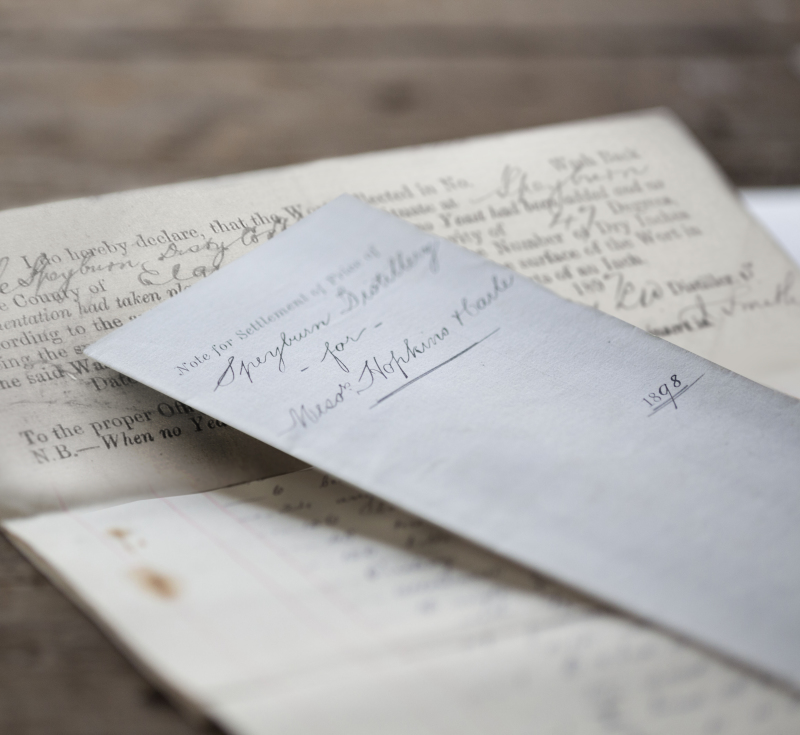

The fundamental process of making whisky has barely changed since John Hopkins produced the very first precious drop of Speyburn whisky on that cold winter night all those years ago.

Today we channel the spirit of our riverside home to produce an exceptionally smooth whisky that can be enjoyed by everyone, everywhere with simple pleasure at its heart and a taste that speaks for itself.

1

1

WATER SOURCE

While hunting for the perfect spot for his distillery, Hopkins discovered the Granty Burn - an untouched freshwater stream hidden in a secluded Speyside valley. He knew that the exceptionally pure water of this burn would produce a remarkable whisky with a naturally refreshing character.

Over 125 years after its founding, Speyburn remains the only distillery to use the pure, crystal-clear water of the Granty Burn.

2

2

MALTING & MILLING

Speyburn goes to great lengths to draw on the best this land has to offer. By sourcing consistently high quality malted barley from our long-standing UK suppliers we ensure that this key ingredient is the perfect first step to creating our award-winning single malt whisky. Before we can fully extract the excellence locked in the grain, our 10 tonne twin-roller ‘Boby’ mill crushes the malt into grist 5.6 tonnes at a time.

3

3

MASHING

The freshly milled grist is placed into our large mash tun, where it is mixed with hot water in cycles, with the temperature increased every time, to convert the starches into a sugar-rich liquid known as wort. Once all the sugar has been extracted, the mixture is cooled and pumped into a large vessel known as a washback ready for the next stage.

4

4

FERMENTATION

We use both stainless steel and wooden washbacks, the latter made of Douglas fir. They are large tanks where wort meets yeast and the fermentation takes place. Yeast metabolises sugars to produce alcohol and carbon dioxide in a spectacle of frothing and churning, this is the most visually spectacular part of the process. Long fermentation times here at Speyburn add to the character of the finished single malt whisky. The strong beer produced at this stage is called ‘wash’ and it already has much of the Speyburn character locked in it.

5

5

DISTILLATION

Sitting proudly at the heart of Speyburn Distillery is one large wash still used for first distillation and two smaller spirit stills for the second. The wash still charges both spirit stills at the same time, an unusual distillation regime which helps us achieve a light yet flavoursome spirit. The stills are of classic Speyside shape, broad at the base with slender necks. They work in tandem with traditional worm tub condensers. This time-honoured method of turning vapour into spirit adds the familiar body and rich character to our whisky.

6

6

MATURATION

It’s here that the Speyburn spirit begins the very longest part of the production process - maturation.

The spirit is poured into air-dried oak casks, which have been seasoned with bourbon or sherry, before being transferred to our traditional dunnage warehouse and left to quietly rest, soaking in all the colour, flavour and aroma of the wood. As the whisky slowly ages, it becomes smoother, sweeter and more flavourful, resulting after many years as the single malt whisky we’re proud to call Speyburn.